Introduction

Deformed bars are the backbone of every construction project. These sturdy, ridged bars give concrete strength and stability, helping structures stand tall and weather the test of time. Whether it’s a home, commercial building, or major infrastructure, their quality plays a huge role in the structures’ success.

However, their performance is only as good as the supplier behind them. A reliable deformed bar supplier in the Philippines makes sure their materials meet the DTI-BPS standard on steel bars and helps keep your project running smoothly.

If you are looking for a reputable supplier, you’ve come to the right place. TKL Steel Corporation is here to guide you in making an informed decision. Keep reading to learn more about the green flags to look for and how to avoid unscrupulous ones.

What Are Deformed Steel Bars and Their Role in Construction?

Deformed bars, also known as corrugated bars, rebars, or “kabilya” in the Philippines, are essential components in construction made from carbon steel. They are used in mechanical anchoring, reinforced structures, and floor slabs.

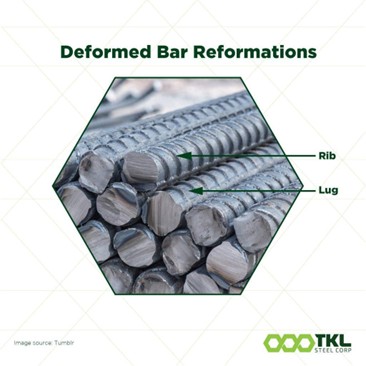

Deformed steel bars feature distinctive lines and rings, called lugs and ribs, positioned at regular intervals along the bar’s length. The lugs ensure a stronger bond between the materials, while the ribs improve anchorage within structures to keep concrete from moving from the bars.

Deformed bars serve two purposes in construction:

- Main reinforcement – Provide the necessary resistance to support structural loads

- Temperature reinforcement – Help prevent shrinkage, elongation, and cracking of concrete.

Why Supplier Reliability Matters

Choosing a dependable supplier is crucial in construction because it impacts the outcome of your project. Here are four reasons why it’s important:

Consistent Quality

Suppliers who consistently offer high-quality materials ensure that every batch of deformed steel bars performs as expected, minimizing the risks of structural issues. With fewer defects or the need for rework, you save time and money.

Availability

Delays are the last thing you want to happen in your construction project. It can drive up your labor costs, after all. For this reason, your supplier should have efficient logistics to deliver deformed steel bars when you need them most.

Competitive Pricing

Reliable suppliers understand the importance of balancing cost with performance to provide you with the best value for your investment. They usually provide a fair deformed steel bar price based on market trends.

Reinforcement Strength

Engineers determine the required grade of deformed bars for a project, so it’s crucial to find a supplier that offers a variety of grades to match those specifications. A reliable supplier ensures that their deformed bars meet industry strength standards, providing durable reinforcement for structures exposed to harsh conditions like high winds and earthquakes.

Signs of a Reliable Deformed Bar Supplier

When you are on the hunt for a deformed bar supplier in the Philippines, there are a few signs that can help you separate the dependable ones from the rest. Knowing the green flags to look for will save you from costly mistakes down the road.

Strong Reputation

Trusted suppliers are known in the industry for always meeting expectations, whether delivering top-notch materials or sticking to timelines. Look for online reviews, testimonials, and recommendations from different contractors or businesses. If your potential supplier has earned others’ trust in the industry, chances are they will deliver the same level of reliability for you.

Transparent Pricing and Consistent Communication

Reliability goes together with transparency, so you can expect a dependable supplier to provide clear upfront pricing without hidden costs. This allows you to plan your budget accurately.

Additionally, your supplier should be with you every step of the way, from confirming orders to providing delivery updates. While problems are inevitable, they must work closely with you to resolve them quickly. If they are responsive and proactive, they take your business seriously.

Ability To Deliver

Your supplier must have the right resources, logistics, and processes to ensure your deformed bars arrive on time. They should have a wide range of deformed bar sizes in stock, including various grades, diameters, and lengths, ensuring they can fulfill your requirements efficiently. Lastly, pay attention to how they handle inquiries about lead times and availability.

Adherence To Quality Standards

Cutting corners on quality is not an option for deformed steel bars. The risks, from repairs to downtime and legal issues, are never worth it.

Superior suppliers won’t cause you headaches with defective batches or materials that don’t meet the specs. They comply with industry standards, ensuring their products meet strict specifications for strength, durability, and performance. Ask for certifications or product samples to verify that the materials meet your needs.

Risks of Choosing an Unreliable Supplier

Partnering with the wrong supplier can derail your construction project in ways you might not expect. Here are ways they can do so:

Substandard Materials

Inferior materials are a disaster waiting to happen. Using poorly manufactured or incorrectly sized deformed steel bars can compromise your structure’s safety. As a result, you spend more time and money fixing the damage than if you’d chosen the right supplier in the first place.

Supply Chain Distribution

An incompetent supplier might promise quick deliveries but fail to support it with a stable supply chain. If they run out of stock at a critical moment, you might end up with wasted hours, missed deadlines, and frustrated clients.

Hidden Costs

Fly-by-night suppliers might offer cheaper upfront prices, but the “savings” they claim can quickly disappear when hidden costs start piling up. For one, low-quality deformed bars can lead to structural failure that requires major repairs. You might also end up liable if the subpar materials cause accidents. What seemed like a bargain could cost you more than you expected.

Purchase High-Quality Deformed Bars From TKL Steel Corporation

As the go-to deformed bar supplier in the Philippines, TKL Steel Corporation takes pride in delivering high-grade materials for your construction needs. Our deformed steel bars are carefully tested to ensure they will do the job, giving you one less thing to worry about. We also work with reputable manufacturers, so you can be confident that you are getting dependable products that will last.

Furthermore, we are invested in your project’s success. That is why you can count on our team to deliver a smooth and hassle-free process, from helping you choose the right deformed bars to ensuring we deliver your orders on schedule.

We offer deformed steel bars in grades 33, 40, and 60, with diameters ranging from 10mm to 36mm. Meanwhile, length options include 6m, 7.5m, 9m, 10.5m, and 12m, offering flexibility to meet the needs of your project. Contact us today to learn more.

Frequently Asked Questions About Deformed Bar Suppliers

Why Is It Important To Choose a Reliable Deformed Bar Supplier?

Working with reliable deformed bar suppliers ensures you receive top-notch materials that meet industry standards at competitive prices. You can have peace of mind knowing your structures are safe and durable through the years.

More importantly, they take a lot of stress out of the process. You can focus on your project knowing your deformed steel bars will show up on time and are unlikely to have defects.

How Can I Tell if a Deformed Bar Supplier is Trustworthy?

To determine if a supplier is trustworthy, start by checking their reputation. Positive feedback and a proven track record are strong indicators that you can trust them with your project. You can also ask for referrals from other contractors to get an idea of what it looks like to work with your potential supplier.

You should also observe how a supplier communicates with you. They should always provide status updates and quickly respond to your questions or concerns. They should also be clear about pricing, delivery schedules, and potential issues. If they are hard to reach, it’s best to stay away.

Lastly, check if they have a solid quality control process. They should provide test reports proving their materials are strong and durable.

What Are the Risks of Working With an Unreliable Deformed Bar Supplier?

Working with incompetent deformed bar suppliers can wreak havoc on your construction project. One of the most serious risks is poor durability. They might provide you with substandard materials, which lack the strength and resilience needed to withstand everyday loads, let alone extreme conditions. You might often need to repair or replace your structure, driving up costs and delaying progress. Worse, it puts not just the project but the safety of everyone who uses the structure at risk.

An unreliable supplier might also contribute to a hazardous working environment. That’s because substandard deformed steel bars increase the likelihood of accidents during and after construction.

Given the devastating consequences of working with the wrong supplier, you must do your research to find the one who provides you with the best.

Conclusion

Choosing a dependable deformed bar supplier goes beyond getting the job done. It’s about getting a partner who understands your needs and prioritizes your project’s success. In an industry where quality is everything, the right one can make all the difference in keeping your project on track, within budget, and up to the highest standards.

At TKL Steel, we always put your best interests first. Get in touch with us today to learn more about our products and services. We look forward to hearing from you!