Steel is essential when it comes to building structures as it provides support. Due to its durability and versatility, structures that are made of structural steel are sturdier. Structural steel is a type of steel construction material that is made with a specific cross section or shape.

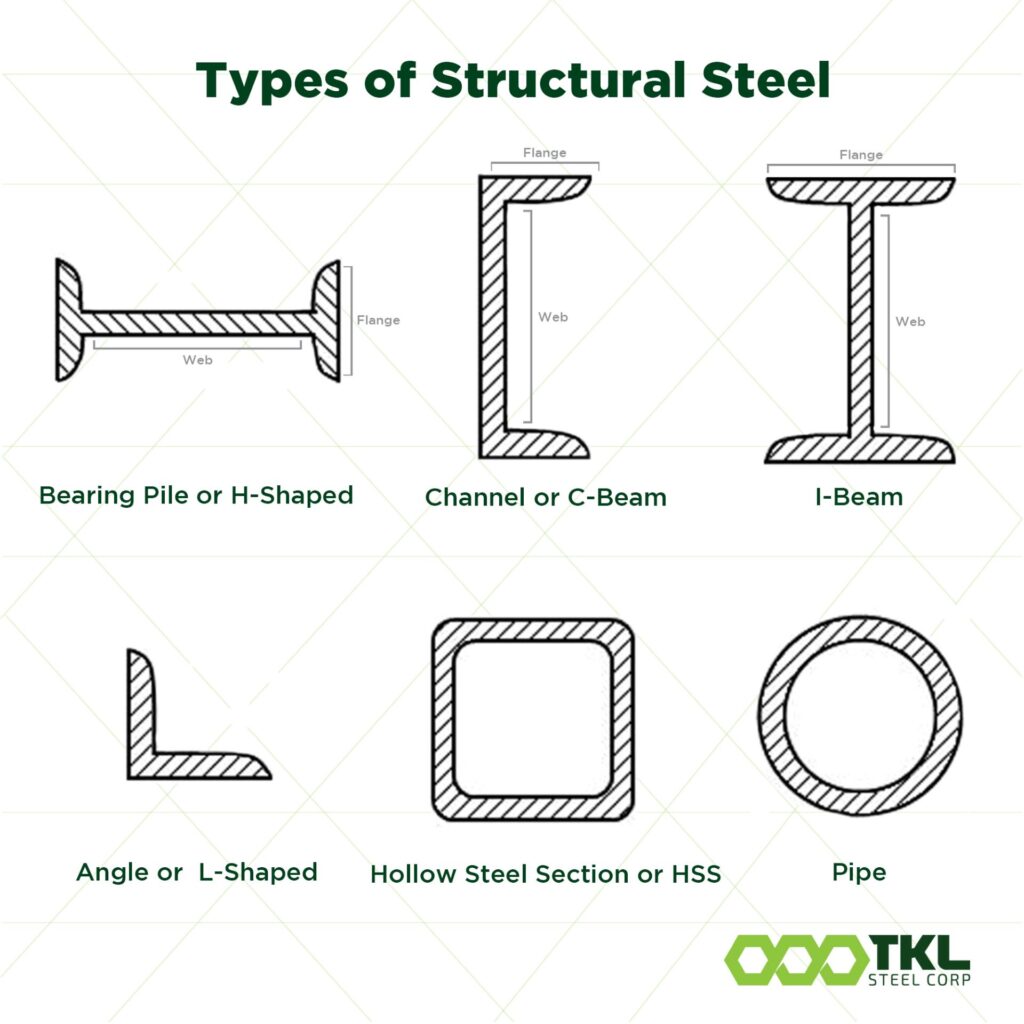

There are various types of structural steel sections that are generally utilized in construction and below are the common types:

1. Angle or L-Shaped

Angle structural steel is an L-shaped beam with two legs at a 90-degree angle, and it comes in equal or unequal legs. This type of structural steel is commonly used for trusses and braces.

2. Bearing Pile or H-Shaped

Bearing Piles or H-shaped beams are used to create deep foundation systems. Builders utilize this type of structural steel for dense soils and construction projects that need to carry heavy loads at limited areas.

3. Channel or C-Shaped

As the name suggests, Channel or C-Shaped Beam has a C-shaped cross section and is formed by two parts – the web that connects the two flanges. This type of structural steel is commonly used for constructing bridges, marine piers and other building applications.

4. Hollow Steel Section or HSS

Hollow Steel Section or HSS can be classified into square, rectangle and round shapes. This type of structural steel is used in construction projects that require carrying of heavy loads of various materials.

5. I-Beam

An I-Beam or H-Beam is a type of structural steel that is formed by two parts – the web that connects the two flanges. I-Beams are ideal for constructing homes, bridges, highway ramps and overpasses due to its great resistance to bending.

6. Pipe

Pipes are hollow cylindrical tubes that come in various sizes. This type of steel is commonly used in sprinkler systems, heat exchangers, and air handlers, as pipes can withstand extreme temperatures.

7. Tee Beam

The Tee or T-Beam is a shaped cross section that has two parts, the top section is called the flange while the vertical section is called the web. T-beams are best used as a load-bearing since it can hold-up large loads of materials.

8. Custom Shapes

Custom shapes are not limited to utilizing the most common type of structural steel. Custom metal fabrication is useful in construction projects that require other cuts rather than the basic shapes. These are utilized in commercial and residential buildings. Advanced tools and techniques are used to cut or fabricate custom shapes such as water jet, laser, and plasma cutting and metal fabricators.

Advantages of Using Structural Steel

Using structural steel in construction projects is beneficial due to its durability and versatility. Aside from these, there are also several other benefits such as:

1. Shortened Construction Time

Since structural steel is pre-engineered to a specific design during the manufacturing, it means that the measuring and cutting onsite is lessened. Once the material arrives on-site, it will be easier to erect and the number of manpower needed is also reduced.

2. Aesthetic Appeal

Structural steel can be bent or rolled to form non-linear sections to enhance its aesthetic appeal. Due to its flexibility and malleability, the designers can explore unique shapes and textures. The aesthetic quality of structural steel emphasizes the structure’s design and complements the steel’s functional characteristics.

3. Sustainability

Structural steel is sustainable as it can be recycled and reused for many times. When a steel-framed building is demolished, its section can be reused.

Common Uses and of Structural Steel

When it comes to the construction of buildings, bridges and other infrastructure, structural steel is the ideal material. Here are the common uses of structural steel:

1. Construction

Structural steel is primarily used for construction purposes due to its inability to be bent and high strength to weight ratio. Structural steel such as the channel bars, beams, and angle bars are utilized to build residential and commercial buildings, warehouses, train stations, bridges, and many more.

2. Vehicle

Structural steel is beneficial in manufacturing various transport vehicles due to its elasticity, ductility, and strength and corrosion resistance. These types of transportation are trucks, aircrafts, ships, and trains to name a few.

3. Energy Infrastructure

Structural steel is also used for fabricating components of various energy sectors such as wind power, nuclear, mining, electric, oil, and natural gas. Structural steel is utilized for manufacturing and constructing transmission towers, turbines, electromagnetic shields, electricity pylons, oil and gas wells, and pipelines. Since it is corrosion resistant, it is able to withstand high temperatures which lessen accidents at sites where structural steel is utilized.

4. Other Applications

Due to structural steel’s ductility and malleability, structural steel can also be used to manufacture machinery and equipment, storage tanks, and tools. It also has a lesser quantity of carbon which is utilized to manufacture household appliances such as refrigerators, washing machines, microwaves and ovens. It can also be used for manufacturing of various food packages such as containers for food and beverages, packaging of chemicals and aerosols. Structural steel lasts for a long time, is recyclable, and is also cost-effective, making it an ideal material for various construction projects.

Are you looking for a trusted steel supplier that provides good quality steel products at competitive prices? Contact TKL Steel Corporation, the trusted steel supplier in the industry with over 35 years of experience in valuing the trust of our customers and providing good quality steel products at competitive prices. For inquiries, you may reach us at 0917 808 8528, 0939 909 0146, (02) 8588 1155, email us at sales@tkl.com.ph or send us a message on our official Facebook page www.facebook.com/tklsteelph and our friendly sales associate will assist you with your steel requirements.

Sources:

Different applications of structural steel – structural steel design. (2018, March 03). Retrieved February 19, 2021, from https://northern-weldarc.com/applications-structural-steel-design/

Media, T. (2016, May 02). 5 reasons why structural steel is such a Popular building method. Retrieved February 09, 2021, from https://www.mscsteel.com/blog/5-reasons-why-structural-steel-is-such-a-popular-building-method.html

Team, W. (2015, November 23). 7 advantages of structural steel frame construction. Retrieved February 09, 2021, from https://www.whirlwindsteel.com/blog/bid/407580/7-advantages-of-structural-steel-frame-construction

The various types of structural Steel Shapes. (2017, April 18). Retrieved February 13, 2021, from https://blog.swantonweld.com/the-various-types-of-structural-steel-shapes