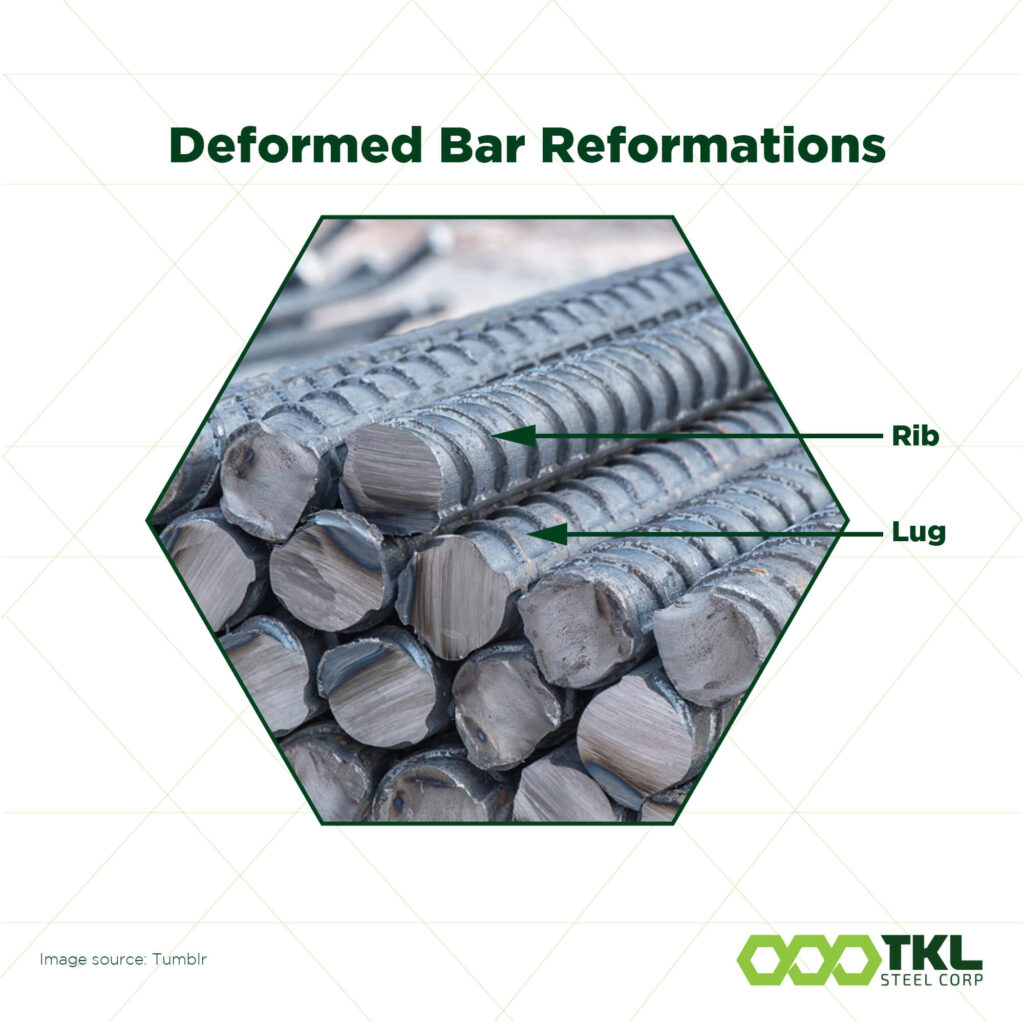

Deformed bar also known as rebar or kabilya is made from carbon steel. It is used as mechanical anchoring and reinforcing concrete for building constructions. If you look closely, you will see lines and rings in the deformed bar which are called lugs and ribs that are usually positioned at regular intervals in all grades of the deformed bars. The lugs reinforce the ribbing pattern by its angular spacing on the exterior of the deformed bar. It gives a stronger connection of the bonds formed between the materials. While the ribs give improved anchorage in concrete structures to hold on to the structures and to avoid movement of the concrete material from the reinforced bars.

Sizes of Deformed Bars

Deformed bars have various grades and specifications that differ in yield strength, chemical composition, and percentage elongation. Grades are equal to the minimum yield strength of the bar and are usually manufactured in grade 33, grade 40 and grade 60. The various grades of deformed bar show the amount of tensile strength it can carry per pound per square inch. The higher the grade, the greater the strength it can provide.

TKL Steel offers various grades to meet low, intermediate, and high-tensile building requirements. Grade 33 is typically used in low-rise buildings with low loading conditions. Grade 40 is typically used in medium rise infrastructures, and grade 60 is used in medium to high rise infrastructures. These grades are available in standard sizes such as 10mm, 12mm, 16mm, 20mm, 25mm, 28mm, 32mm and 36mm. The available lengths of the deformed bar are 6m, 7.5m, 9m, 10.5m and 12m.

| Grade | Diameter (mm) | Length (m) |

|---|---|---|

| 33 | 10, 12, 16, 20, 25 | 6, 7.5, 9, 10.5, 12 |

| 40 | 10, 12, 16, 20, 25, 28, 32, 36 | 6, 7.5, 9, 10.5, 12 |

| 60 | 10, 12, 16, 20, 25, 28, 32, 36 | 6, 7.5, 9, 10.5, 12 |

Rerolled bar is also available in 1.25 kilo, 1.4 kilo, 1.7 kilo, 1.9 kilo and 2.2 kilo, which is commonly used in bundling the deformed bars for concrete reinforcement and for aesthetic purposes.

Uses of deformed bars

Deformed bars are used for main reinforcement and temperature reinforcement. Main reinforcement gives the resistance needed to support the loads required while temperature reinforcement is utilized to avoid shrinkage & elongation of concrete and to prevent cracks.

Advantages of using deformed bars

Deformed bars are commonly used in various construction projects due to the following benefits:

1. Modulus of Elasticity

Steel is an elastic material as it can expand in tension up to 200GPa without breaking and distorting its shape. Deformed bars are placed inside the concrete to prevent tension stress, making cracks in the concrete less likely to happen.

2. Resistance

Steel can withhold rough situations during transportation, storage, packaging, and placing on construction site. If minor damage occurs, it does not significantly affect its performance.

3. Long-lasting & sturdy

Rebar is an ideal option of reinforcement as it works well with concrete. The greater exposure of the rebar to the concrete, the stronger the hold will be.

4. Ability to withstand extreme temperatures

Rebars are beneficial due to its characteristic to remain sturdy despite being exposed to extreme temperatures. The rebar and concrete work well together since they expand and contract at the same rate.

Types of deformed bars

Deformed bars have various types that are used in construction.

1. Carbon Steel

Carbon Steel, also known as “black bar” is the most common type of deformed bar. Carbon Steel is versatile, however it corrodes, which is not ideal in areas that have high humidity or structures that are visible to water.

2. Welded Wire Fabric

Welded Wire Fabric is manufactured from a series of steel wires prepared at right angles and electrically welded at all steel wire crossing. This is utilized in walls and structural floor slabs, road pavement, box culverts, drainage structures, and in small concrete canals.

3. Sheet-Metal

Sheet-metal is made of anneal sheet steel pieces fabricated into corrugation of one-sixteenth inch deep with holes cut at regular spacing. This type of rebar is utilized in floor slabs, stairs and roof construction.

4. Epoxy-coated

Epoxy-coated are costly and utilized in areas that are exposed to salt water. This type of deformed bar can withstand corrosion.

5. European

European rebars are made of manganese which makes it easier to bend. This type of rebar is durable but is not ideal to use in areas that are prone to earthquakes, hurricanes, and tornadoes.

6. Stainless Steel

Stainless steel type of rebar that can be utilized as a substitute reinforcing steel bar with carbon steel requirement. It is a type of rebar as it can withstand corrosion and damage.

7. Galvanized

Galvanized rebars are more resistant to corrosion compared to carbon steel rebar. The rebars are immersed in molten zinc to protect it from corrosion. This type of rebar is utilized for structures that are exposed to extreme weather conditions.

8. Expanded Metal or Wire Mesh

Expanded Metal or Wire Mesh Rebars are formed by a shearing sheet of steel into parallel lines that are stretched to form a diamond or square shape between each cut. This is utilized on sidewalks, small concrete pads and other surfaces that do not carry heavy loads.

9. Glass-Fiber-Reinforced-Polymer

Glass-Fiber-Reinforced-Polymer is made from carbon fibre. This type of rebar is the most expensive among all. It will not corrode in any conditions making it the ideal material that will last for a long time.

Are you looking for a trusted steel supplier that provides good quality steel products at competitive prices? Contact TKL Steel Corporation, the trusted steel supplier in the industry with over 35 years of experience in valuing the trust of our customers and providing good quality steel products at competitive prices. For inquiries, you may reach us at 0917 808 8528, 0939 909 0146, (02) 8588 1155, email us at sales@tkl.com.ph or send us a message on our official Facebook page www.facebook.com/tklsteelph and our friendly sales associate will assist you with your steel requirements.

Sources:

Rahman, F. (2018, September 17). What is rebar? Types and grades of steel reinforcement. Retrieved April 17, 2021, from https://theconstructor.org/practical-guide/steel-reinforcement-types-grades/24730/

Rodriguez, J. (2019, October 15). These rebar types are alternatives to regular steel reinforcement. Retrieved April 17, 2021, from https://www.thebalancesmb.com/types-of-rebars-844455

Vera, A. (2020, December 02). 5 benefits of the Reinforcing Bar. Retrieved April 17, 2021, from http://www.buzzillablog.com/5-benefits-reinforcing-bar/